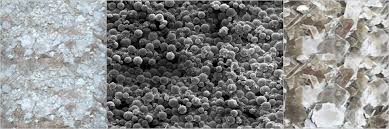

Cenospheres are sometimes also called as microspheres that are widely used in a variety of materials from plastics and caulking to paints and finishes. Although, they are sometimes also used in concrete. Cenosphere from India consists a range of uses in concrete countertops including:

- A lightweight aggregate – cenospheres can be treated as a substitute of the normal-weight sand that is used in concrete. They have a density that is less than water (approx. 0.7 vs water’s 1.0); quartz sand particles typically have a density of about 2.65 which means that 1 pound of cenospheres takes up the similar absolute volume as about 3.8 lbs of sand.

- A workability enhancer and extra-fine aggregate – Cenospheres are known for their very small spherical particles. As such they act just like minute ball bearings in a concrete mix. By adding cenospheres to a conventional weight concrete mix will increase workability because of its ball bearing effect and since they are also structural aggregate, they expand concrete density and strengthen it by providing a better packing. Furthermore, the added fines mend the trowelability and finishability. Usually dosages of 1% to 5% by weight of aggregate are added to a concrete mix to improve the workability.

- A bulk filler and shrinkage reducer in cement grouts – Meanwhile Cenosphere from India have very fine particles and are generally light in color; they are perfect for the use in cement grout slurry. By adding the bulk from the cenospheres, it not only increases the volume of grout without adding more cement, but also the fine aggregate gradation of the particles supports to reduce the shrinkage. In spite of everything, cement grout is still a kind of concrete, so the same rules apply. Finally, the spherical shape marks packing pinholes at ease and more effective because of the polishing action delivered by the particles. And the spherical shapes are further likely to “roll” into small holes better than pointed or angular crushed particles. Typical cenosphere measured quantity is approximately around 10% to 30% by weight of cement.