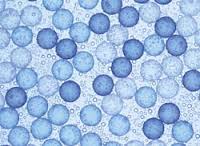

A Cenosphere is a type of hollow microscopic ball that is made up of smooth silica and aluminum and other minor ceramic elements. A Cenosphere is also known as Ceramic sphere. Cenospheres are derived in the coal power plants. It has been used for more than 30 years over the world. It has helped us in improving the qualities of many manufactured products in India. When the coal is burnt in thermal power plants, it produces a fly ash that contains ceramic particles that is made largely of alumina and silica. The particles that are produced in the process of coal burning, produces a part of fly ash. In India, Cenospheres are largely made up of silica, iron and alumina. The size of a Cenosphere ranges from 1 to 500 microns that have an average compressive strength of 3000+ psi. Cenospheres are widely used in a variety of products as fillers in low density concrete. Cenospheres are used in plastic and composite materials that are used for producing bowling balls, surfboards, kayaks, in fire bricks, in floor tiles, in insulating materials and in automotive components. Cenosphere are described as the multifunctional filler that mixes well in binders and resins.

Most of the Cenospheres are scooped up or take out from ash ponds. Ash ponds are the place where the fly ash is carried out when the wet disposal takes place in the thermal power plants. Some of the Cenospheres gets collected by themselves at the thermal power plants. The wet microspheres that are collected in the ash ponds are then dried up then processed to specifications and then it is packed up to meet customer requirements. All the Cenospheres that we see are not similar in nature. In fact, all of them are quite different from each other. The property of Cenospheres depends on the consistency of the coal used and it also depends on the operating parameters of the thermal power plant. If the manufacturer makes two things constant, that is, the consistency of the coal used and the operating parameters of the thermal power plants, then the Cenosphere processed would be quite constant.