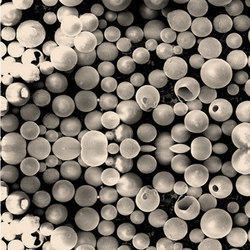

A cenosphere is an inert, lightweight, and hollow sphere that is largely made up of silica and alumina filled with air and inert gas, which is usually produced at thermal power plants as a byproduct of coal combustion. Generally, the color of the cenosphere ranges from gray to almost white with a density of about 0.4-0.8 g/cm3 (0.014-0.029 lb/cu in) which contributes as a great buoyancy. As a result, cenosphere is exclusively considered as a free flowing powder that is comprised of hard-shelled, tiny, and hollow spheres collected from coal ash. Because of these qualities, the demand for the cenosphere exporter has immensely increased as the byproduct consist of higher particle strength, lower value of thermal conductivity, ultra-low density, and impermeability that is suitable for its usage in various industries. The particles are 75% lighter compared to other different minerals which are used as fillers in clay, talc, and calcium carbonate and 30%, furthermore, lighter than general pitches. The great finished outcome of cenosphere is immeasurable like tiles of space boats, flying machine coatings and oil well bonds.

However, several techniques have been evolved over the last 50 years to mend the metal values from the coal ash. Different studies have focused on the extraction of alumina, carbon, magnetite, cenosphere, and several other metal values. The elements present in coal ash, aluminum, and iron have been tested by the cenosphere exporter to ensure the quality of the particles. Regaining of element components from coal ash has been proficient for its use in the both physical and chemical processes.

For recovering the major constituents of coal ash, a chemical processed test is been formulated and scaled-up in four general categories, that is:

- Hydrothermal leaching

- Sinter-leach

- Gas solid reaction

- Direct reduction

Therefore, the cenosphere exporter exports the fly ash particles to multiple industries for various purposes:

- Foam insulation

- Coal ash mineral wool

- Fly ash fire bricks

- Decorative glass

- Filler application

- Light weight refractories

- Fire abatement application

No comments:

Post a Comment