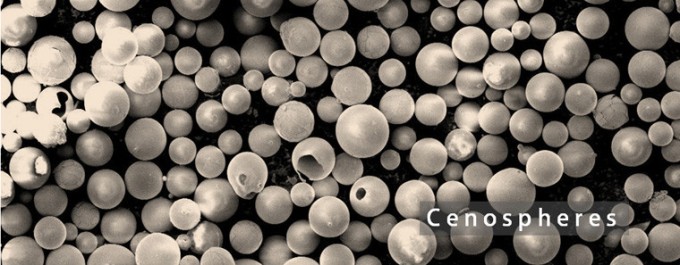

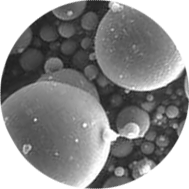

Cenospheres

are inert hollow silicate spheres. They are largely used to reduce the

weight of Plastics, Rubbers, Resins, cement etc. used widely as stuffing

lubricants in oil drilling operations under high heat and high-stress

conditions down the hole. Also used as oil well cementing, mud putty and

other related applications. Cenosphere exporters

use it for an extended plastic compounds, as they are well-suited with

plastisols thermoplastics, Latex, Epoxies, Phenolic resins, Polyesters,

and urethanes. The compatibility of Cenospheres with special cement and

adhesives coating and composites have been well recognized. Cenosphere

is broadly used in a range of products, including sports equipment,

automobile bodies, insulations, paints and fire, marine craft bodies,

and heat protection devices.

Cenosphere exporter exports the cenosphere having chemical properties as:

- Silica: 50-60%

- Aluminum: 33-39%

- Iron Oxide: 1.3-5%

- Calcium: 0.5-1.5%

- CO2 Gas: 70%

- Manganese: 0.8-1.5%

- Nitrogen Gas: 30%

What is the type cenosphere exporter use to export?

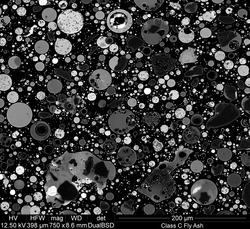

Fly

Ash: It is one of the residues generated in the combustion of coal. Fly

ash is generally taken from the chimneys of power generation, where the

bottom ash is removed from the foot of the furnace. Before, fly ash was

usually released into the atmosphere with the smoke stack, but today

pollution control equipment has mandated to capture the ashes earlier to

release. Conditional upon the source and character of the coal being

burned, the mechanisms of the fly ash produced vary significantly, but

all fly ash includes generous amounts of silica (silicon dioxide, SiO2)

(both amorphous and crystalline) and lime (calcium oxide, CaO).

ASTM

618F: Fly ash is defined into two classes by ASTM C618- Class F fly

ash, and Class C fly ash. Both the classes differentiate each other on

the basis of the amount of silica, calcium, iron, and alumina present in

the ash. Thus, the chemical properties of the fly ash are generally

influenced by the chemical contamination in the coal burned.

The

burning of harder, older anthracite and bituminous coal typically

produces Class F fly ash, whereas Class C fly ash is produced from the

burning of younger lignite or sub bituminous coal, in addition to having

pozzolanic properties, also has some self-cementing properties.