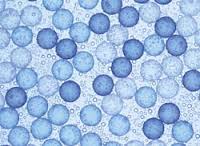

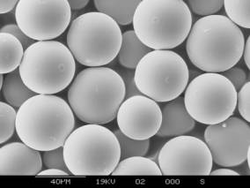

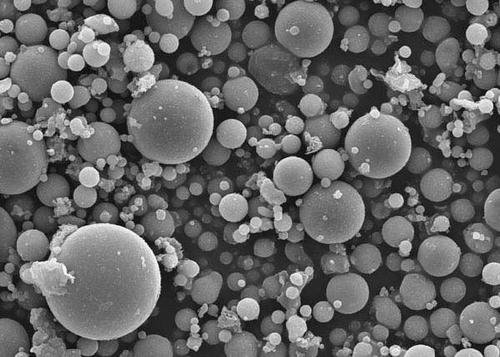

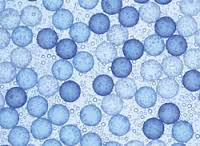

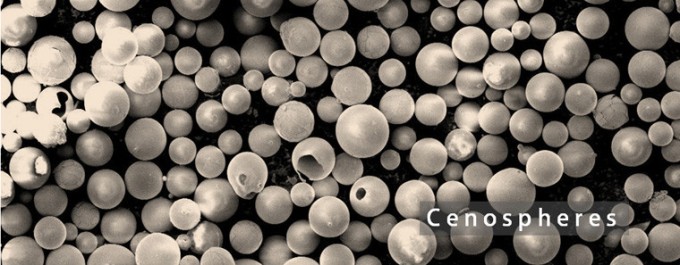

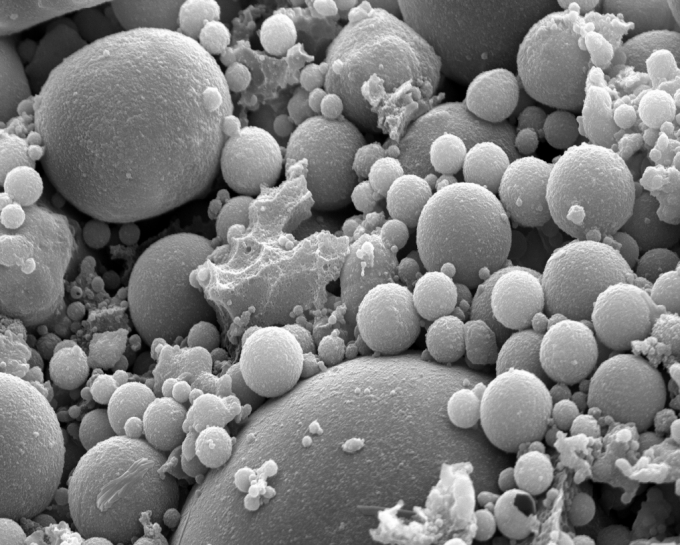

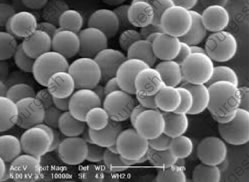

Cenospheres are unique free-flowing particles composed of hollow, hard-shelled, minute spheres. A small portion of the PFA (Pulverized fuel ash) formed from the combustion of coal at the thermal power plant is produced as cenosphere India. It is assumed that only about 1 percent of Cenosphere is produced in fly ash from thermal plants due to their hollow and low-density nature and they float in the lagoons where fly ash is discharged. Cenosphere largely consists of Silica, Iron, and alumina. The size of the particles varies ranging from 1 to 500 microns, having an average compressive strength of 3000+ psi. They are alternatively also referred as hollow spheres, microspheres, microballoons, hollow ceramic microspheres, and glass beads. When the hollow spheres float in the lagoons, they are collected and further isolation is carried by froth floatation and then dried. The final application is carried out in a pneumatic conveying system which is connected to a tribo electric separator. In this separator, the ash is divided into three fractions and the cenosphere particles are then separated from iron and carbon. The end product is then used for a variety of applications.

What is fly ash?

As mentioned above, it is considered that only about 1 percent of cenosphere India is produced in the fly ash during the coal combustion in thermal power plant. When coal is burned at a combustion temperature approximately of about 2800oF, the non-combustible ores occurring naturally from coal combustion forms bottom ash and fly ash. According to the cenosphere suppliers in India, bottom ash is a light-weight aggregate component which tumbles to the boiler bottom for collection; whereas, fly ash is carried off with the flue gases. Fly ash particles are then collected and stored in silos for testing and then utilized in different applications for its beneficial chemical and physical properties.

Fly ash material is used widely for its several beneficial characteristics like it increases strength and durability of the application. Further, fly ash particles are less disposed to chemical attacks such as de-icing salts and soil sulfates and thus, alleviate the negative effect of deleterious aggregates.