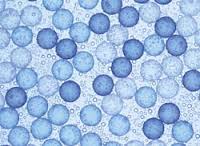

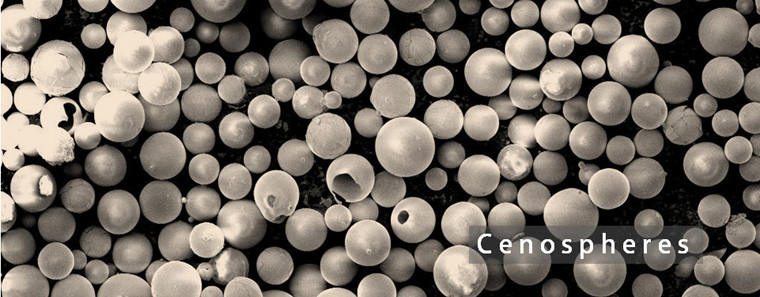

The word Cenosphere is derived from two Greek words ‘Kenos’ which means hollow or void and ‘Sphaera’ which means sphere or round, that literally means ‘hollow spheres’. A Cenosphere is a type of hollow sphere, light weighted and inert that is made of silica and alumina. It is produced as a byproduct of coal combustion at thermal power plants. Cenosphere are light, hard and rigid, waterproof and insulative. It is excellent light-weight filler. This property of light weight makes them useful in a variety of products, especially in fillers. Nowadays, Cenosphere are used in cement as fillers to produce low density concrete. Now, some of the manufactures have started mixing Cenosphere with metals and polymers to make them light weight. In other words, Cenosphere is also known as Hollow Ceramic Microspheres. The density of Cenosphere is about 0.4-0.8 g/cm3 that is, 0.014–0.029 lb/cu in, this property gives them great lightness. Their color varies from gray to almost white.

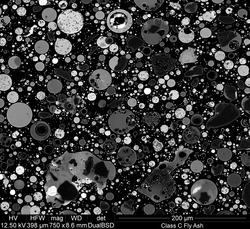

Cenosphere are occurred naturally as a byproduct of the burning of coal in thermal power plants. The burning process of coal in thermal power plants produces fly ash of coal that contains ceramic particles that is made of Alumina and Silica. The process of coal burning and the fly ash is produced at temperatures of 1,500 to 1,750°C that is (2,730 to 3,180 °F). It is formed through complicated physical and chemical transformation. The chemical composition and structure depends upon the composition of coal that generated them.

Here are some of the uses of Cenosphere:

- In synthetic foams, Cenosphere are used as filler. It gives us a number of benefits such as adding strength to foam, reducing costs, thermal protection etc.

- For years, Cenosphere have been used in oil drilling. It is used to lower the density of a petroleum cement paste.

- It is often used in paints and coating to regulate infra red radiation.

- The properties of Cenosphere such as re-formable, strength etc don’t let the thermosetting and thermoplastics shrink. This is the reason that Cenosphere is being used for years in manufacturing polymers and plastics.